Common problem 2022-07-19

Market Research of Thermal Spraying Industry

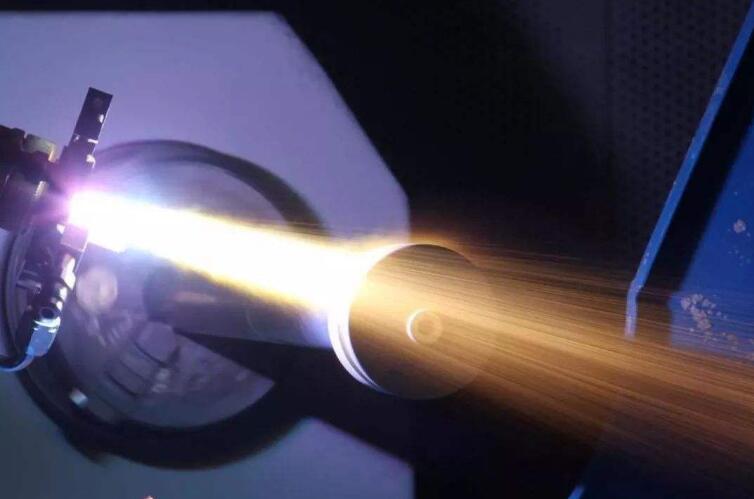

Thermal spraying technology has been widely used due to its wide range of coating materials, fast deposition rate, high flexibility, easy automatic processing and strong adaptability. Statistics show that a foreign advanced aero-engine needs more than 5000 parts for thermal spraying, which means that thermal barrier coating has become one of the key technologies of high performance aero-engine manufacturing. In addition, according to foreign statistical reports on the application of high-performance ceramic coatings, thermal spraying ceramic coatings accounted for two thirds of the high-performance ceramic preparation market in North America, which is basically consistent with the domestic reports that the output value of thermal spraying is about one third of all the output value of surface technology, indicating that thermal spraying technology has become one of the important surface engineering technologies.

From the perspective of application, aviation is the largest application market of thermal spraying. Although the global epidemic has had a certain degree of adverse effects on the aviation industry, it still has a steady development trend in the next few years. For gas engine, thermal spraying coating can give it good wear resistance and corrosion resistance, prolong the service life of engine components, improve fuel efficiency and reduce loss. The application field of gas engine is also expanding, including locomotives, ships, helicopters, tanks, motorcycles and so on, which has a positive role in promoting the application of thermal spraying technology.

Thanks to the boost of the aviation industry and automobile manufacturing industry, North America is the largest market for thermal spraying coatings. For example, the development of Mexico aviation market, the increase of automobile industry and oil and gas exploitation have brought positive factors to this region, which is helpful for the application of thermal spraying technology. The Asia-Pacific region has the fastest development speed in the application of thermal spraying technology in the next few years, mainly due to the strong development of the aviation industry, automobile industry and oil and gas industry in China, India and other countries and regions. In Europe, the research and development investment in the pharmaceutical industry continues to increase, the huge potential market of Russian crude oil and natural gas industry and the improvement of oil recovery technology have made the thermal spraying market in the region develop smoothly.

According to the report of R & D Institute of Market Depth Analysis and Investment Strategy Research Report of Thermal Spraying Technology Industry in China from 2021 to 2026, thermal spraying technology in China was established in the late 1940s. In order to eliminate foreign technical restrictions on China and meet the special needs of national defense in the 1970s and 1980s, some military departments and aviation departments vigorously engaged in thermal spraying technology research. Beijing Institute of Mining and Metallurgy first developed a series of self-adhesive primary spraying powder. In the late 1980s, the State Economic and Trade Commission and the Committee on Science and Technology jointly convened the first thermal spraying technology promotion conference in China and established a national thermal spraying cooperation group. In the following four consecutive “five-year plan”, thermal spraying technology was taken as a national key promotion project and policy and financial support were given. The 12th Five-Year Development Plan of Iron and Steel Industry requires China’s iron and steel enterprises to further promote energy conservation and emission reduction, form high-strength, high-durability, corrosion-resistance, high-temperature resistance and wear-resistance product manufacturing technology, further promoting the application of thermal spraying technology in the iron and steel industry.

During the “13th Five-Year Plan” period, China should complete the low-carbon target of 40% ~ 45% reduction in carbon emissions per unit of GDP by 2020 compared with 2005, and lay the foundation for the medium and long-term low-carbon development goals proposed in the Joint Statement on Climate Change between China and the United States to reach the peak of carbon emissions around 2030. At the same time, it is necessary to achieve obvious results in environmental indicators such as air pollution prevention and control. The 13th Five-Year Plan of the Coatings Industry pointed out that high construction efficiency and low pollution coating technologies such as high-pressure airless spraying, air-assisted airless spraying, high pressure airless electrostatic spraying and thermal spraying should be promoted. The 13th Five-Year Development Plan of Safety Production Standards pointed out that the mandatory standards of painting operation ought to be revised. The revision includes the general requirements for occupational health and safety of painting, the safety requirements for architectural painting, the safe operation of electroplating production, the safety technical conditions of electroplating production equipment and arc thermal spraying equipment, the safety performance test of ventilation and purification equipment, and the acceptance of safety facilities of painting engineering.

The demand of civil and military applications and the advancement of science and technology have accelerated the development of thermal spraying industry in China in recent years. The rapid development of civil market has stimulated the growth of material consumption scale. The demand of military industry has essentially driven high quality and new thermal spraying materials to practical application. China’s thermal spraying industry has formed a scale. It is estimated that there are about 1500 units engaged in thermal spraying technology research and development or production in China. With the promotion of thermal spraying technology, the application of various thermal spraying materials has penetrated into almost all industrial fields of national economy, such as aerospace, metallurgy, machinery, petrochemical, electric power and automobile, as well as national defense and military industry. At present, it has entered a new stage of rapid development, and its application fields have been continuously expanded. It has played an increasingly important role in the manufacturing of new parts and repair of old parts of various industrial components, extending the durability of components or materials, or endowing materials with special properties.

Analysis on Development Prospect of Thermal Spraying Industry

Thermal spraying can meet the needs of higher performance or significantly prolong the durability of components by endowing the surface of the material with excellent functions. It also helps prolong the overall life of the material by recycling the components. Thus, resource consumption is reduced and resource utilization efficiency is improved. It is of great significance to further promote the application of thermal spraying technology today when China vigorously promotes the circular economy and builds a conservation-oriented society. Corrosion and abrasion are the main reasons for the failure of materials and components. It is reported that the economic losses caused by this in developed countries account for about 3% ~ 5% of the GDP. China’s annual losses caused for this reason have reached hundreds of billions of dollars, which should be partially recovered by thermal spraying protection. Therefore, thermal spraying technology has broad application space and great potential in national economic development.

RELATED DEVELOPMENTS

Common problem 2022-07-19

Company dynamics 2022-07-19

Industry information 2022-06-06