Common problem 2022-07-19

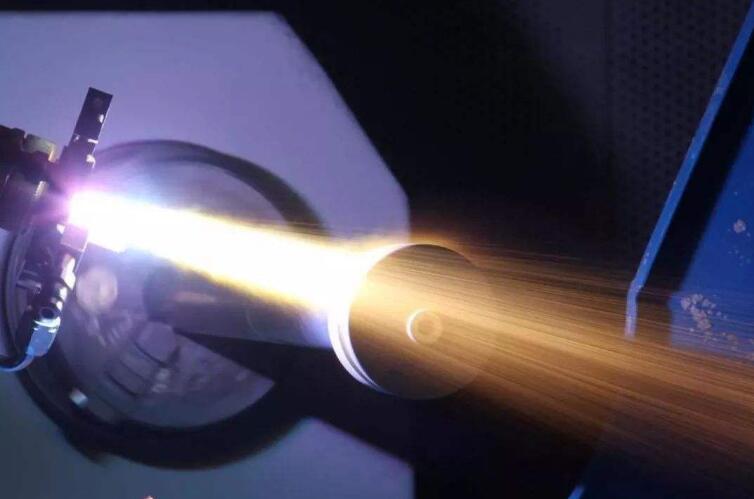

In metal manufacturing industry, spraying tungsten carbide is a common metal coating. It has a series of outstanding characteristics, such as corrosion resistance and wear resistance.

Tungsten carbide is a kind of fine powder with gray color. Tungsten carbide powder can be sintered and pressed into jewelry, cutting tools or engineering machinery parts. However, sprayed tungsten carbide is formed when it is combined with a small amount of metal powder (usually cobalt, chromium or nickel). It is sprayed to form tungsten carbide coating on the surface of metal objects.

Although tungsten carbide is a fragile ceramic material, it is mixed with cobalt, chromium and nickel when used as a tungsten carbide coating. This metal ceramic composite coating combines the ductility of metal materials and the high hardness of ceramic tungsten carbide to obtain excellent properties.

Tungsten carbide has many potential applications, including thermal spraying tungsten carbide coating. These tungsten carbide coatings are very common on the brake discs of high-performance vehicles. In this application, tungsten carbide coating improves the performance and maintenance interval, and reduces the brake dust.

One of the important applications of tungsten carbide is to manufacture tools for processing. These tools attach importance to the wear resistance and heat resistance of materials. They are usually used for high precision or mass production of steel wear too fast. Such materials or their variants are also commonly used, such as tungsten-cobalt carbide composites, for piercing armoured ammunition.

The strength of tungsten carbide is also very common in mining and foundation drilling. In the field of sports, it is usually used as the top part of the mountain rod or ski rod. Spraying tungsten carbide is usually used for jewelry and surgical equipment. For the surgical equipment, it provides better performance than stainless steel. But it’s more expensive and requires more sophisticated processing.

RELATED DEVELOPMENTS

Common problem 2022-07-19

Company dynamics 2022-07-19

Industry information 2022-06-06